MicroConcrete roofing tiles

The tevi MicroConcrete Roof tile production unit can produce up to 350 MicroConcrete Roof (MCR) tiles per day

The tevi MicroConcrete Roof tile production unit can produce up to 350 MicroConcrete Roof (MCR) tiles per day

The tevi MicroConcrete Roof tile production unit includes:

- One vibrating table machine with short chassis and electric motor of 12 V 8A.

The machine also works with a car battery or solar panels (not included). - AC inverter from 110-120V a 12 V 8A

- 200 plastic moulds to start producing roman tiles

- Metal frames for roman tiles, ridge tile and vault slabs

- Scale and spoons for dossification

- Basic testing equipment (quality control) for the workshop

- Spare parts kit and maintenance tool

- Printed manuals, training video and CD-ROM

- NEW: Now includes the Ridge Closer Tile frame

The tevi MicroConcrete Roof tile

production unit includes all the KNOW-HOW

The tevi MicroConcrete Roof tile production unit is ready to start producing:

- Roman tile

- Ridge tile

- Verge tile at 90º

- Mini vaults

The tevi MicroConcrete Roof tile production unit works with an AC Inverter or by itself with car batteries or solar panels

Follow this links for more information :

Prices and more information

Frequently asked questions

Pieces produced with the tevi MicroConcrete Roof tiles production unit

Minimum floorplan of a MicroConcrete Roof tile production factory

Photos: MicroConcrete Roof tiles manufacture

Photos: Roofs with MCR technology

Photos: Tile, ridge tile, verge tile at 90º

Photos: Ridge closer tile

Photos: Mini vault

production unit is recommended

as the best in its class by the

Basin Network

Pieces produced with the tevi MicroConcrete Roof tiles production unit

|

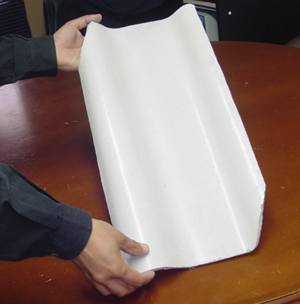

Mini vaults

The mini vault is a system used for ceiling and roof slabs. It saves up to a 40% against a traditional concrete floor or ceiling. Follow this link to see some applications of the MicroConcrete mini vaults |

|

Verge tile at 90º (left). Ridge tile (right)

The Verge tile at 90º (left) is an accessory to roof finishing. The Ridge tile is an accessory to cover the joints in a roof. Follow this link to see some applications of the Verge tile and the Ridge tile |

|

Ridge closer tile accessory

(NOT included in the standard package!)   This Ridge closer tile accessory closes the space between the ridge tile and the roof tile. Follow this link to see some applications of the Ridge closer tile accesory |

Ridge tile and verge ridge tile at 90º

|

MicroConcrete Roof (MCR) tile production unit

The tevi MicroConcrete Roof tile production unit can produce up to 350 MicroConcrete Roof (MCR) tiles per day

The tevi MicroConcrete Roof tile production unit can produce up to 350 MicroConcrete Roof (MCR) tiles per day

The tevi MicroConcrete Roof tile production unit includes:

- One vibrating table machine with short chassis and electric motor of 12 V 8A.

The machine also works with a car battery or solar panels (not included). - AC inverter from 110-120V a 12 V 8A

- 200 plastic moulds to start producing roman tiles

- Metal frames for roman tiles, ridge tile and vault slabs

- Scale and spoons for dossification

- Basic testing equipment (quality control) for the workshop

- Spare parts kit and maintenance tool

- Printed manuals, training video and CD-ROM

- NEW: Now includes the Ridge Closer Tile frame

The tevi MicroConcrete Roof tile

production unit includes all the KNOW-HOW

The tevi MicroConcrete Roof tile production unit is ready to start producing:

- Roman tile

- Ridge tile

- Verge tile at 90º

- Mini vaults

The tevi MicroConcrete Roof tile production unit works with an AC Inverter or by itself with car batteries or solar panels

Follow this links for more information :

Prices and more information

Frequently asked questions

Pieces produced with the tevi MicroConcrete Roof tiles production unit

Minimum floorplan of a MicroConcrete Roof tile production factory

Photos: MicroConcrete Roof tiles manufacture

Photos: Roofs with MCR technology

Photos: Tile, ridge tile, verge tile at 90º

Photos: Ridge closer tile

Photos: Mini vault

production unit is recommended

as the best in its class by the

Basin Network

Moulds for MCR tiles

Production of good quality equipment implies very high tooling costs, and production of lesser quality equipment is likely to result in many unsatisfied customers and tiles that do not live up to standard.

Tile making process in Tevi machine

The basic steps are: mortar making, mortar vibrating, curing, pool curing and drying.