Of cement, chocolate & rum

Although many trendy bars now serve chocolate mojitos, a Swiss and Cuban mix is not obvious. Yet, when it comes to cement, Swiss, Cuban and Indian scientists have tackled one of the world’s lesser known but biggest challenges. As countries develop, demand for housing and infrastructure increases. Concrete is by far the most commonly used construction material to meet these needs, and cement is required to make concrete.

As the Cuban economy reforms, demand for construction materials is growing extremely fast; demand for cement is expected to grow by over 70% over the next 3 years. Cuba currently does not have the production capacity in place to sustain that growth. Furthermore, cement production is carbon and resource intensive.

One of Cuba’s challenges is to find ways of producing more cement with existing clinker production capacity, to meet growing demand with a reduced environmental impact.

One of Cuba’s challenges is to find ways of producing more cement with existing clinker production capacity, to meet growing demand with a reduced environmental impact.

Prof. Fernando Martirena Hernández, leader of the Cuban LC3 team said: “The challenge of meeting the sudden increase in cement demand gives Cuba the unique opportunity of choosing a low carbon path towards development through the introduction of LC3 at a large scale, as the only viable option in the very short term. In the mid to long term, LC3 could also allow Cuba to preserve valuable resources whilst yet meeting development needs”.

The answer came from a long standing cooperation between the École Polytechnique Fédérale de Lausanne in Switzerland and the Universidad Central de las Villas in Cuba. A unique mix between fundamental material science and hands on field tests have shown that abundantly available low grade kaolin clay could be used as an alternative, low carbon, raw material. The initial results from the field trials in Cuba were confirmed by a broader project that involved a range of research and development organisations in India.

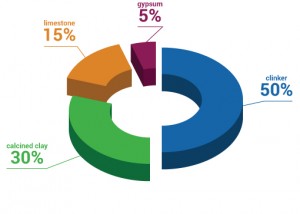

LC3, as this new cement came to be known, makes it possible to nearly double the quantity of cement produced from the same quantity of limestone by substituting a large portion of clinker (an intermediary material made by heating limestone at very high temperatures) with calcined clay.

Limestone Calcined Clay Cement (LC3) has the potential to reduce CO2 emission by 20-30% compared to traditional cement; a major reduction considering that cement accounts for 5-8% of today’s manmade emissions.

Limestone Calcined Clay Cement (LC3) has the potential to reduce CO2 emission by 20-30% compared to traditional cement; a major reduction considering that cement accounts for 5-8% of today’s manmade emissions.

LC3 is a low-carbon and low-cost cement that delivers similar or even superior performance properties compared to Portland cement. The blend can be easily manufactured in existing production lines, requiring only minor capital investments.

“The potential impact of the LC3 project is very significant. After water, concrete is the most used material in the world. Any emissions reduction will have a substantial impact”, explains Professor Scrivener who heads the LC3 project. “LC3 can become an essential construction material, especially in fast-growing emerging economies where minimising environmental impact and resource depletion are a top priority”. It is estimated that using LC3 instead of regular cement can save up to 500 million tonnes of CO2 per year by 2050 (equivalent to the emission of the UK or Canada). “If we want to advance the sustainability of concrete – its cost, availability and environmental footprint – we have to act before demand increases exponentially”, says Scrivener.

Industrial scale pilot projects were implemented in Cuba and India, and in both countries several structures were successfully built using the cement. Cuba will be the first country where LC3 will be produced at a commercial scale. It will enable to meet growing demand without large capital investments and whilst lowering the impact on the environment.

A chocolate mojito with a nice twist.

For more Information, please contact:

École polytechnique fédérale de Lausanne

Mr. Rob Fielding

Tel: +41 21 693 10 28

This email address is being protected from spambots. You need JavaScript enabled to view it.

Universidad Central de las Villas

Facultad de Construcciones/Faculty of Constructions

José Fernando Martirena Hernández (Prof. Dr.Sc. Ing.)

Tel: +53 42 205872 ext 102

This email address is being protected from spambots. You need JavaScript enabled to view it.